Since my shop-time is limited, a system that produces tight joints quickly and efficiently is very appealing. That is why I chose the Kreg K3 Master Pocket Hole System. I’ve had my eye on it for awhile, and now I’ve added it to my arsenal. I look forward to the different projects I could use this for. I think it would prove especially useful for shop fixtures and face frames for cabinets.

Since my shop-time is limited, a system that produces tight joints quickly and efficiently is very appealing. That is why I chose the Kreg K3 Master Pocket Hole System. I’ve had my eye on it for awhile, and now I’ve added it to my arsenal. I look forward to the different projects I could use this for. I think it would prove especially useful for shop fixtures and face frames for cabinets.

I thought I’d share some of my first impressions of the product itself.

I chose the Kreg K3 Master Pocket Hole System because it had everything I needed in one kit. I don’t need to go out and piece-meal the system together. Its nice to have a kit that’s ready to go, right out of the box.

Here’s what came with my system:

- Drill Guide Block

- Benchtop base

- Portable base

- Spacer

- Face clamp

- Material support stop

- Dust collection shroud

- Stepped drill bit with depth collar

- Allen wrench

- 6-inch square driver

- 3-inch square driver

- Starter screw set

- Starter plug set

- Carrying case

- Instruction manual

- Instructional DVD

The Jig

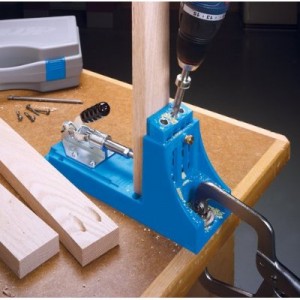

I’m impressed with the quality of this jig. Its cast in a very dense plastic which looks impossible to break. The drill guides are encased in hardened steel, so you won’t wear out the jig with repeated use. The clamping mechanism is spring loaded and adds a very strong grip. All of the pieces work smooth without any slop.

The base has a depth gauge to set the length of your step drill bit. This eliminates the guesswork and cumbersome measurements.

You set the depth of the cut using a scale on the side of the drill block. The marks are nice and deep, so you won’t wear them away. Unfortunately, they are a little hard to see. I found a white crayon from my son’s color box and rubbed the edge. Then with a paper towel, I buffed away the rest. What remains is white crayon inside the indentations, which makes it much easier to read.

The jig also comes with a portable base. You slide the drill guide block inside the portable base and clamp to extra large pieces. The extra flexibility will certainly come in handy. You can even use the drill block by itself. This is especially useful in tight spaces. Adding spacer blocks to the drill guide block compensates for different thicknesses.

The system also comes with a few extras. The dust collector shroud easily hooks to your shop-vac for mess-free drilling. An adjustable stopblock is also included for repeated drilling. The stop can swing out of the way when you don’t need it.

The included face clamp is great. Very tight fit and will keep everything aligned while you drive the screws home. It would be handy to have another one, but certainly not necessary.

Also included are the square head drivers for your drill and the drill bit itself. Not much to say about these. They are what they are.

Quite honestly, I can’t imagine how you can wear out this jig. It is constructed very well and should last you a lifetime. I also like the flexibility it offers. I should be able to use this jig anywhere, anyplace.

Screws and Plugs

The master system comes with a sampler of screws and plugs. But don’t get too excited. They only offer you a few of each so you can test drive your new jig. So, if you’re thinking that you’re going to go home and build a project with the enclosed screws and plugs, you’re going to be disappointed. Go ahead and play with the screws and plug samples and get a feel for how the jig works. Once you know what you really need, jump in the car and get the ones you’ll need for your project. The manual has a nice chart that shows you what screws you need for the type of wood you’ll be using.

Here’s what came in my sample packet:

- #7 x 1″ screws (10)

- #7 x 1 1/4″ screws (10)

- #8 x 1 1/4″ screws (10)

- #8 x 1 1/2″ screws (10)

- #8 x 2 1/2″ screws (10)

- White plastic plugs. (6)

- Paintable wood plugs (5)

Storage Case

For the tools I only use occasionally, I really like having a storage case. It keeps all your bits and pieces together without losing them in some forgotten drawer. While I’m glad to have a storage container for my new Kreg jig, the storage case is a bit lacking. Its nothing more than a box where you throw your stuff in. There are no dividers or areas to organize your tools. So when you open the box, you have a mess. It would be nice if each part had its own place. Things stay neat and organized, and with a glance, you can see if you’re missing something.

Manual & Training DVD

The manual claims to be detailed, but its far from the case. It has some illustrations to show the parts and the assembly, but it doesn’t actually show you how to use the tool. Instead, Kreg relies on the included DVD to show you how to use the jig. While the DVD is nice, it would be better to have some shop reference available without running inside to pop in a DVD. With that said, the jig is super easy to use. So I guess in the end, its really not an issue. I’m just sayin’.

The manual includes a handy chart that helps you choose the right screw for the job. I’m sure I”ll be using that plenty. I might even photocopy it and tape it to the inside of my case.

The DVD is about 30 minutes with a menu so you can jump directly to the info you need. The DVD is broken up into two main sections. The first section deals with the basic operation of the Kreg jig. This is pretty detailed and explains how to choose the right screw, set the depth of the drill bit, and adjusting the drill guide block.

The second section is called Skill Builders. These videos tackle specific scenereos where the Kreg jig can be used. I like this section because it gives you plenty of ideas on how to use your new pocket hole jig. The video cover faceframes, leg and rail joints, edge joining, making repairs and more. I found most of the skill builder videos on Kreg’s YouTube channel.

Kreg K3 vs K4

When I decided I wanted the Kreg pocket hole jig, I was a little confused as to which one to buy and the difference between the two. So I thought I’d compare the two versions they have available.

When I decided I wanted the Kreg pocket hole jig, I was a little confused as to which one to buy and the difference between the two. So I thought I’d compare the two versions they have available.

As far as I can tell, the difference between the K3 and the K4 is the location of the toggle for the clamping mechanism. The K3 has the toggle in the front whereas the K4 has the toggle in the back. Given the choice, I would opt for the K3 system with the toggle in the front. Not only is it more convenient, but it’s almost necessary if you are trying to clamp a large panel. You simply couldn’t reach around a large panel to toggle the clamp.

The other difference is how you secure your jig to your work surface. The K4 system has a nice little area at the front of the jig that is a perfect fit for their face clamps. This way you can easily clamp the jig to your workbench. Unfortunately, when moving the toggle to the front of the jig (as with the K3), you lose that clamping location. If the jig needs to be secured, you’ll have to mount the jig to your work surface (or bench-hook) with screws.

The other difference is how you secure your jig to your work surface. The K4 system has a nice little area at the front of the jig that is a perfect fit for their face clamps. This way you can easily clamp the jig to your workbench. Unfortunately, when moving the toggle to the front of the jig (as with the K3), you lose that clamping location. If the jig needs to be secured, you’ll have to mount the jig to your work surface (or bench-hook) with screws.

Wrap it up!

There you have it. I’m very pleased with my purchase. I’m excited to start using it on some of my larger projects. I even have a few home improvements lined up that will use this jig on. While I appreciate fancy joinery, sometimes you just gotta get it done. The Kreg K3 pocket hole jig will certainly get it done.

Oh, be sure to stop by the Kreg website. They have a few plans you can download for free. They’re great skill builders and quick projects to break in your new Kreg pocket hole jig.